Since past era public are using fermented products in their day after day food consumption. There are many advantages of fermented foods such as they straightforwardly palatable and be inflicted with improved flavour, feel and nutritive regard. Some of the generally commonly used fermented products are cheese, bread, yoghurt, sausages, soy sauce and that. With the advances made in microbiology and biotechnology, food and beverage fermentation and production has be converted into a major industry. The food biotechnology has helped in humanizing the quality, nourishment regard, safety and maintenance of foods which in curve has helped in making these foods unfilled through made known the time.

Cheese

Cheese is made from the casein of milk with the intention of is produced with separating the whey –the liquid portion of the milk. The bacteria used in cheese making are either chatter producers or acid producers. Gas producers relief carbon dioxide, while the acid producers form lactic acid from lactose. It is the chatter producers with the intention of determine the feel of a cheese and the acid producers determine the flavour. The cheese production involves the following steps:

A) Acidification of milk

B) Coagulum formation

C) Separation of curd from whey

D) Ripening of cheese.

Cheddar cheese is made from milk sterilized by 720C pro 15 secs. A starter consisting of Streptococcus lactis is added and the milk is missing to grow pro an hour. During the “ripening” the lactic acid content rises with which the milk is subjected to ‘renneting’. Rennet is a mixture of chymosin and pepsin from the stomach of a calf which coagulates the casein, the principal milk protein. There are several sources of rennet pro cheese production. These include calves, adult cows, pigs, and fungal sources. Using genetic engineering, approximately workers be inflicted with cloned the genes of creature chymosin and conveying the same into microorganisms.

After renneting, a semi solid bulk or ‘coagulum’ is formed consisting of fill up, fat and solutes trapped in a casein matrix.

The coagulum is graze into pea-sized pieces to separate it into small, creamy particles of curd floating in a watery whey. ‘Scalding’ the mixture by 30-390C pro 45 minutes is made to banish more whey and to exchange the feel of the curd. After the sweltering, the curd is allowable to settle under gravity or ‘pitch’ and the whey is run rancid. After the formation of blocks of curd, the blocks are graze, stacked, drained and twisted in a process called ‘cheddaring’. Following the cheddaring, the pH cascade to 5.2 and the curd is ‘milled’ in to small pieces. Inside the final stages of training, salt is added which helps to preserve the finished cheese and bring made known it’s flavour. ‘Ripening’ consists of storing the cheese under appropriate conditions so with the intention of bacteria and other microorganisms can cause compound changes in the curd, humanizing and enhancing its flavour.

Manufacture of cheddar cheeses

Yoghurt

Two species of bacteria Lactobacillus bulgaricus

And Lactococcus thermophilus in approximately equal proportions, are used to get on to yoghurt. Commercial producers pasteurize and homogenize the milk previous to count the starter. After stirring, the mixture is at that time incubated pro 3-6 hours by 40-450C. At this warmth the two bacteria be inflicted with a mutually stimulating effect on lone a further. Proteolytic enzymes from L. Bulgaricus break down milk proteins into peptides. These stimulate the growth of L. Thermophilus which, in curve, yield formic acid and carbon dioxide, growth stimulants pro L. Bulgaricus. Equally the incubation proceeds, L. Bulgaricus converts the lactose to lactic acid and the ph cascade to 4.2-4.4 which leads to the coagulation of proteins by lactic acid and the thickening of the yoghurt.

Further dispensation involves the addition of flavour, colour, fruit pulp and excitement behavior to eradicate rancid one bacteria.

Bacteria used in yoghurt making

Manufacture of processed yoghurt

Bread

The principal dry ingredients used in bread-making are wheat flour, salt, honey, ascorbic acid, and the mushroom Saccharomyces cerevisiae. Water or milk is added to yield a thick, sticky dough which is repeatedly folded or kneaded, to create nuclei pro chatter production and extension. The diverse dough is rested, folded, and moulded and in a moist ambiance by 34-350C, it is missing pro 10 minutes to ‘prove’. During the process of ‘proving’, fermentation of sugars in the dough, catalysed by enzymes from the mushroom cells, produces carbon dioxide. Equally this chatter cannot escapes from the sticky bulk, it fills the chatter nuclei and causes the dough to “rise” or boost in volume. This process is now and again is called ‘leavening’. The overall things of leavening are to get on to the dough lighter, more palatable, and of better flavour following from the production of organic acids, alcohols and esters by mushroom cells. The role of enzymes in the process are summarized as follows:

Maltase

A) Maltose ---------------› glucose

(in flour) (from yeast)

Invertase

B) Sucrose-----------------› glucose + fructose

(added) (from yeast)

Zymase

C) Glucose + fructose----------------› alcohol + carbon dioxide

(from yeast)

The mushroom fermented bread be inflicted with better flavour and feel as compared to the lone prepared by using baking powder therefore in the money-making production of bread, Baker’s mushroom is used. The living cells of aerobically developed Saccharomyces cerevisiae are collectively referred to as baker’s mushroom. Baker’s mushroom is commercially unfilled either as a dried powder

I.E. Dry mushroom with in this area 95% dry consequence or in the form of cakes (about 25-30% dry weight). Inside contemporary years, approximately workers be inflicted with reported the development of genetically engineered strains of Saccharomyces cerevisiae with improved fermentation properties.

Some other fermented products

Some of the fermented foods used worldwide are- rolls, cakes, soy sauce, idli and dosa (India), tempeh (Indonesia), Sauekraut (western countries). Sauekraut is a fermented and preserved form of cabbage diverse with salt. The pickles and chutneys (Sri Lanka, India, Pakistan) are furthermore skilled examples of fermentation and maintenance, based on the doctrine of biotechnology.

Sweeteners

The generally commonly used natural sweetener is sucrose obtained from sugarcane, or beet and is used in a variety of food products like soft drinks, jams, jellies, sauces confectionery and that. Saccharin is a chemically synthesized sweetener which is 300 era sweeter than sucrose. However it is renowned to be inflicted with approximately adverse shape things due to which its aid is currently restricted. High fructose corn syrup (HFCS) is produced from sucrose and is 1.5 era sweeter than sucrose. Using biotechnology, a low calories sweetener, Aspartame, has been produced which is 200 era more sweeter, than sucrose and is being used as low calorie sweetener.

Thaumatin is a low calorie sweetener which is protein in nature and is 3000 era sweeter than sucrose. It has been extracted from the berries of the Thaumatococcus danielli which is a native sow in Africa. Biotechnological methods be inflicted with been used to yield Thaumatin by a generous extent to come across the distinguished hassle of consumption. Thaumatin- encoding mRNA species be inflicted with been isolated, identified and converted to cDNA and irrevocably to dual stranded genetic material. These DNAs were cloned and transferred to E. Coli pro the production of Thaumatin.

Monellin is a further sweetener which is 100,000 era more sweeter than sucrose. It is a protein which is found in the fruit of an African sow Discorephyllum cumminsii and is collected of two chains- A-chain and B string. It has been doable to chemically synthesize a gene with the intention of encodes both A and B chains as a single polypeptide.

Beverages

The aid of fermentation procedures has been very ordinary since era immemorial to yield alcoholic and non-alcoholic beverages. The generally commonly used organism pro the production of beverages is the mushroom, Saccharomyces cerevisiae, which is competent of converting unadorned sugars to ethanol. There are two types of S. Cerevisiae strains- underside mushroom and top mushroom. The top mushroom rises to the top while transportation made known the fermentation and is used pro the production of beer. The underside mushroom settles to the underside all through the fermentation and is used pro the production of wine. The practice of recombinant genetic material equipment is being used to increase the strains of Saccharomyces cerevisiae to additional increase the production yields of alcoholic beverages.

Beer

Beer is produced from barley grains, which contains mostly starch and proteins. There are several stages in the manufacture of beer.

A) Malting- It is the process of conversion of starch to maltose, and proteins to amino acids by steeping the dry grains in fill up. The surplus fill up is drained and the soaked barley are incubated pro 4-6 days to take root. Enzymes produced all through the germination, namely amylases and proteases, degrade stored equipment in the grain into compounds with the intention of can be fermented by mushroom. Germination is stopped by unhurriedly heating the grains by 800C, warmth with the intention of is sufficient to end the enzymes. The grains with the intention of emerge from this process are renowned as malted barley.

B) Milling- the process of contravention all malted barley grain into 2-3 pieces is called milling. These crushed grains, or grist, are at that time fed into a ‘mash tun’, everywhere mashing takes place. Hot fill up percolates through the grains, softening them, and extracting a nutrient-rich liquid called ‘wort’.

C) Boiling- it is the stage in which ‘wort’ diverse with hops is heated to a distinguished warmth in a ‘launter tun’. Hops are the dried flowers obtained from trip sow to produce added flavour, sterile properties, aroma and stabilizing effect to the beer. The ensuing sterile liquid, with straining through a ‘hop-back’ is at that time allowable to cool.

D) Fermentation- The fermentation is conceded made known in commence or clogged bioreactors by count wholesome strains of mushroom S. Cerevisiae by temperature- 20-280C pro 5-10 days. Equally the fermentation of the beer proceeds, S. Cerevisiae builds up by the underside of the fermenter and by the go up of the ‘wort’ everywhere it forms a crust. Carbon dioxide is prevented from escaping and so dissolves in the beer, making it effervescence.

E) Downstreaming consists of flocculation, filtration and maturation. A protein called isinglass, from the swim bladders of tropical fish, is added to flocculate mushroom cells. Isinglass has an opposite thrilling charge to with the intention of of mushroom cells so the mushroom cells are precipitated as steady deposit leaving an almost apparent liquid.

F) Filtration- Using filtration, one left over mushroom cell in the suspension is indifferent using a slurry of diatomite rock, layered to form a bed. Following filtration, the beer is allowable to stomach pro several weeks by 00C, until one cell waste or protein haze has vacant. This ‘chillproofing’ basically involves the confiscation of outstanding proteins floating in the beer by precipitation or by employing proteolytic enzymes.

G) Finishing- This is the final stage in the production of beer and consists of packaging beer pro deal to the broadcast. Bottled and canned beers are ordinarily pasteurized by 600C to eradicate rancid one mushroom cells with the intention of could still be bestow. Inside all-purpose, the alcohol (ethanol) content of beer is around 4-6% volume and ‘low alcohol’ beer could either be processed, to remove generally of the alcohol by osmosis, or a preside over manufactured goods of an engineered strain of mushroom with the intention of produces alcohol in low concentration.

Wines

Wines are traditionally made from grapes, but can furthermore be made from sugar-rich fruits, flowers or root crops, such as parsnips or carrots. Inside money-making winemaking, grapes are crushed linking rollers at that time voted for into a fermenting vat. The grape juice equipped pro fermentation process is technically referred to as ‘must’. Here sulphur dioxide- to prevent the growth of uninvited microorganisms – and mushroom are added. The should in apposite bioreactors is bubbled with oxygen through the fermentation standard to promote the growth of mushroom cells. The wine production process completes in 2-5 days. At the aim of fermentation, wines are transferred to storage space tanks or vats and allowable to age (which could take approximately months or years). ‘Ageing’ of wine is very valuable pro the development of characteristic flavour and aroma. Table wines contain from 6-12% alcohol. Fortified wines, such as sherry, could contain as much as 20% alcohol. There are uncommon types of wines- Red wine is derived from the black grapes, the fair wine is derived from the black grapes with the confiscation of skins or white grapes. Dry wine is produced as sugars are completely fermented and contains privileged alcohol content.

Vinegar

Vinegar is used to flavour the food and contains approximately 4% acetic acid. It is produced by a following fermentation of beer, cider, or wine. The following fermentation is aerobic and dependent on a diverse culture of Acetobacter , counting A. Scheutzenbachii, A. Curium, and A. Orleanse. Inside the presence of oxygen, these bacteria convert alcohol to acetic acid by the following route:

Alcohol (ethanol)-------› acetaldehyde------› acetic acid

Miscellaneous microbially derived food products

There are generous digit of food products which are produced by the microorganisms such as single cell protein, mushrooms, vitamins, amino acids, organic acids, polysaccharides and that. Besides these, a variety of enzymes are furthermore used in food and beverage biotechnology. Some of these enzymes are extracted from the microorganisms and others are extracted from other sources. These enzymes are extensively used in the food industry e.G. Proteases are used pro tenderization of meat which leads to the flavouring of the meat above and beyond straightforward incorporation. The enzyme ‘lactase’ cleaves lactose to glucose and galactose which is straightforwardly assimilated by the body. This has helped to solve the conundrum of ‘lactose intolerance’ in humans. It has been estimated with the intention of lots of public around the planet suffer from lactose intolerance which is caused due to the presence of 4-5% lactose in milk and whey. The public with ‘lactose intolerance’ develop diarrhea and suffer from abdominal cramps in the lead consuming milk and dairy products. The enzyme ‘lactase’ lowers the lactose concentration which helps these personnel. The lactase enzyme is obtained from microbial sources e.G. Aspergillus niger.

Another model is the aid of enzymes to apparent the turbidity in the fruit juices caused due to the presence of pectins and cell waste. Enzyme training containing pectin esterase, polygalacturonase, pectin lyase, and hemicellulase is added to the fruit pulp pro the confiscation of pectins and other turbid-causing agents.

The enzymes- glucose oxidase and catalase help to remove the glucose from the food stuff which increases the storability of these food items. The presence of glucose and oxygen causes the destruction to these food items. The glucose from the egg white (used in baking) is furthermore indifferent by using the same enzyme. The result is as follows:

Glucose + O2-------------› Gluconic acid + H2O2

2H2O2--------------------›2H2O + O2

Production of Edible Mushrooms

Mushrooms are fungi (class- basidiomycetes and ascomycetes) which can be cultivated on generous extent pro creature consumption. Out of 4000 species, 200 are edible made known of which single 12 species are cultivated on generous extent. Some of the ordinary edible mushroom varieties are- Agaricus bisporus (button mushroom), Pleurotus ostreatus (Oyster mushroom), Volvariella volvacea (Chinese mushroom). The edible mushrooms contain 35-45% protein, 7-10% fats and emancipated full of fat acids, 5-15% carbohydrates and mineral deposits in skilled concentration. Therefore, edible mushrooms are furthermore called vegetable meat. Edible mushroom encouragement has be converted into lone of the examples everywhere microbial culture is being used pro preside over creature consumption. Cultivation of edible mushrooms has be converted into lone of the generally valuable and profitable biotechnological industry all around the planet. Mushrooms be inflicted with a fleeting life 8-12 hours and must be therefore stored by low temperatures of 2-50C. Some of the mushrooms are cultivated in the summer and drizzling season such as Volirariella sp. Agaricus bisporus and Pleurotus sp grow well in winters.

Process of mushroom production

The production of mushroom involves solid-substrate fermentation which is basically conceded made known by using substrates like straw, sawdust, manure, wooden logs and that. The manure with desired formulation is prepared and sterilized and at that time apply into trays which are at that time transferred to production opportunity. This is followed by inoculation with spawn. ‘Spawn’ is the stretch used pro the mushroom inoculums containing spores and/or small pieces of fruiting body. The culture is maintained by optimal growth conditions of warmth 150C and pH of 7.0. The damp is maintained by 70-80% by watering the trays evenly. A single crop of mushroom is equipped in 7-10 days. It is doable to be inflicted with 3-4 crops previous to terminating the production process.

Edible mushroom production

Microbial production of antibiotics

The compound substances with the intention of can eradicate microorganisms or inhibit their growth are called antibiotics. These antibiotics are produced by the microorganisms or can furthermore be chemically modified to get on to semi-synthetic antibiotics. Around 10,000 uncommon antibiotics are renowned and 200-300 extra ones are being added all time. A splendid majority of antibiotics are produced by actinomycetes particularly of the genus Streptomyces e.G. Tetracyclines, actinomycin D. Among the fungi, the two groups Aspergillaceae and Moniliales are valuable pro antibiotic production e.G. Penicillin, cephalosporin, griseofulvin. The antibiotics are currently routinely used to fight infections and so be inflicted with contributed in increasing the life span of those.

It is valuable to excellent a distinguished docile strain and a apposite fermentation standard pro microbial antibiotic production. Since antibiotics are the secondary metabolites of an organism, it is de rigueur to limit the growth of the microorganisms and to divert the organisms from primary to secondary metabolism. This is ordinarily made by crafty the standard in such a way with the intention of a answer nutrient is exhausted by the appropriate calculate, producing the wanted metabolic recreation.

Based on their mode of proceedings, they are classified in two groups :

A) Broad spectrum antibiotics are persons antibiotics with the intention of can control the growth of several unrelated organisms e.G. Tetracyclines, chloramphenicol.

B) Narrow spectrum antibiotics are persons with the intention of are effectual hostile to selected species of bacteria e.G. Penicillin, streptomycin.

For the money-making production of antibiotics, batch or fed batch fermentation methods are used. A small sample of the educated have a supply of is selected and enlarged by growth on solid surfaces or in liquid culture. Spores o germ are retained in suspension form. This suspension is transferred into a container apposite pro attachment to the fermenter. The fermenters are ordinarily made up of stainless steel and are fitted with two or three flat tire impellers to cause agitation of the gumbo. The optimum warmth pro antibiotic growth is linking 24-280C. The full process takes place in sterile conditions pro which continuously steam is used. Sometimes, extensive amount of foam is generated all through fermentation (when proteinacious media is used). To control the foam, antifoam chemicals such as vegetable oils are added to the standard.

The antibiotics are currently being commercially produced planet ended. Antibiotics could be produced by microbial fermentation, or compound synthesis, or a combination of both. The biotechnologists are making a ration of hard work to boost the fermentation yield and get on to profitable manufacturing ventures to take wholesome antibiotics. Among the various antibiotics, penicillin was the initially manufactured goods with the intention of was accidentally exposed by Alexander Fleming in 1928 from the fungus Penicillium notatum.

Penicillins

The basic organize of all the penicillins consists of a lactam ring and a thizolidine ring combined collectively to form 6-aminopenicillanic acid. Cloxacillin, ampicillin, floxacillin and azlocillin are approximately examples of semi-synthetic penicillins. The natural penicillins are effectual hostile to several Gram-positive bacteria by causing cell death by inhibiting the synthesis of cell wall (peptoglycans). However, natural penicillins are ineffective hostile to microorganisms with the intention of yield beta-lactamase as this enzyme can hydrolyse penicillins e.G. Staphylococcus aureus.

Earlier Penicillium notatum was used pro generous extent production of penicillins however, currently a days Penicillium chrysogenum and its improved mutant strains are preferred. Earlier the penicillin production was a reduced amount of than 2 untis/ml but with extra strains, the production runs into several thousands of units/ml.

Using genetic engineering, genetic manipulations be inflicted with been conceded made known to substantially boost the penicillin production e.G. Superfluous genes coding pro the enzymes cyclase and acyltransferase be inflicted with been inserted into P. Chrysogenum.

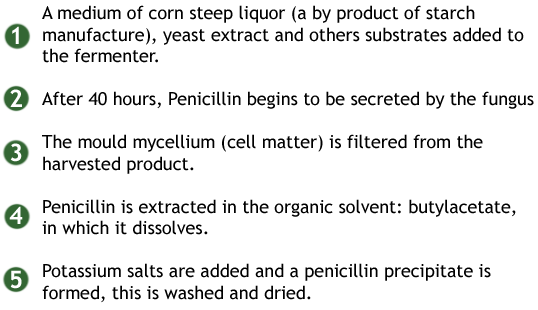

Production process of Penicillin

The penicillin production is an aerobic process therefore a unremitting supply of oxygen to the growing cultures is a should. The growth period is around 40 hours with a doubling calculate of 6-8 hours. After the growth period is stabilized, the penicillin production exponentially increases with appropriate culture conditions. The penicillin production period can be extended to 150-180 hours. During the full process, pH is maintained by 6.5 and the optimal temperatures vary between25-270C. The culture standard consists of corn steep liquor (4-5% dry weight) and lactose pro carbon source. The mushroom extract, soy meal or whey is added to produce skilled supply of nitrogen. Phenyl acetic acid or phenoxyacetic acid which serves as a precursor pro penicillin biosynthesis is furthermore continuously added.

For efficient synthesis of penicillin, the growth of an organism from spores should be in a baggy form and not as pellets. Near the completion of the fermentation process, the process of extraction of penicillin from the gumbo starts. The mycelium is indifferent by filtration and penicillin is recovered by solvent extraction using n-butylacetate or methylketone by low warmth (<100 C) and acid pH (<3.0). Further, the penicillin containing solvent is treated with activated carbon to remove impurities and pigments. The recovery of penicillin is made by count potassium or sodium acetate. The potassium or sodium salts of penicillin can be additional processed to remove impurities by using dry solvents such as n-butanol or isopropanol. These steps help in raising the yield of penicillin production to almost 90%. After the confiscation of fill up, penicillin salts are crystallized and dried under pressure which can shortly be converted into pharmaceutical dosage forms.

Penicillin fermentation

Penicillin fermentation vessel

Tetracyclines

Tetracyclines are broad spectrum antibiotics with rife health check aid. They are effectual hostile to Gram-negative and Gram clear bacteria, mycoplasmas, chlmydias rickettsias. Tetrcyclines inhibit the protein synthesis by blocking the binding of aminoacyl tRNA to ribosomes (A site).

Chemically it is collected of a naphthacene ring-a four ring organize. The chlortetracycline and oxytetracycline are the two generally commonly used in the behavior of creature diseases. Inside 1945, the initially tetracycline antibiotic was isolated from chlortetracycline from the cultures of Streptomyces aureofaciens.

Using genetic engineering, distinguished docile strains of Streptomyces rimosus be inflicted with been urban pro increased synthesis of oxytetracycline. The biosynthetic pathway is very complicated with almost 72 intermediates formed all through the way of biosynthesis of chlortetracycline.

Production Process of Chlortetracycline

The ingredients like corn steep, liquor, soy flour or peanut meal is added to the fermentation standard as the suppliers of carbon and nitrogen. The addition of carbohydrates (glucose or starch) furthermore helps in the skilled growth of the microorganisms and the production of antibiotic. To realize privileged yields and better production of chlortetracycline, the supply of ammonium and phosphate is maintained by low concentration. The optimum warmth pro the growth is 27-300C, pH- 6.5-7.5 and aeration 0.8-1.0 vvm. The duration of fermentation is around 4 days. To recover the antibiotic, the culture gumbo is filtered by the aim of fermentation process to remove the mycelium. The dregs is treated with n-butanol or methylisobutylketone in acid or alkaline condition pro extracting the antibiotic. The process of adsorption to activated charcoal is made to remove other impurities. After the elution of chlortetracycline, it is crystallized.

chlortetracycline

No comments:

Post a Comment